AMS ASME ASTM pro inconel625 mixtura navigantium

AMS ASME ASTM pro inconel625 mixtura navigantium;

Inconel 625 Bars Inconel 625 Inconel 625 Inconel 625 Inconel 625 Inconel 625,

Communes Trade Names: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 non magneticum est, corrosio et oxidatio resistens, chromium nickel-alaymus.Excelsa vis Inconel 625 oritur ex concretione molybdaeni et niobii in chromium nuclei basi mixturae perdurantis.Inconel 625 ingentis resistentiae habet amplis ambitus mordaces solito graviores inclusos effectibus summus temperatus sicut oxidatio et carburization.Praeclara eius vis et spissitudo in iugis temperaturae a temperaturis cryogenicis usque ad caliditatem caliditatis usque ad 2000° F (1093° C) derivantur imprimis a solida solutione effecta metallorum Columbii et molybdaeni in nickel-chromium matricis.

Inconel 625 Compositio chemica

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Maximilianus. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.014 | 0.4 | 0.4 | 0.014 |

Inconel 625 Physica

| Density | 8.4 g/cm³ |

| Liquescens punctum | 1290-1350

|

Inconel 625 Typical Mechanica Properties

| Status | Distrahentes fortitudo Rm N/mm² | Cedat imperium Rp 0. 2N/mm² | Prolongatio sicut% | Brinell duritia HB |

| Solutio curatio | 827 | 414 | 30 | ≤220 |

Inconel 625 signa et Specificationes

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3;

UNS N06625, Werkstoff 2.4856

| Filum | Sheet | Exue | Rod | Pipe | |

| AMS 5599, AMS 5666, AMS 5837, AMS 5979, ASTM B443 | ASTM B443 | AMS 5599, AMS 5979, ASTM B443 | ASTM B 446 SAE/AMS 5666; VdTÜV 499 | Inconsutilem Pipe | iuncta Pipe |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Available in Sekonic Metals

Inconel 625 Bars & Rods

Vectes rotundi/Flat vectes/Hex vectes, Magnitudo A 8.0mm-320mm, Usus est pro valvis, claustris, aliis partibus parce

Inconel 625 filum glutino

Copia in filo glutino et filo vernali in coil forma et longitudine incisa.

Inconel 625 sheet & plate

Latitudines usque ad 1500mm et longitudinem usque ad 6000mm, Crassitudo ab 0.1mm ad 100mm.

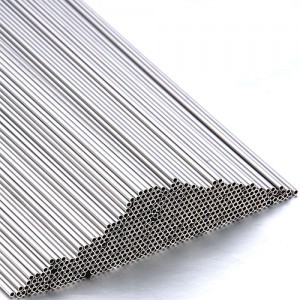

Inconel 625 inconsutilis fistula & iuncta fistula

Signa magnitudinis et dimensio nativata cum parva tolerantia a nobis produci possunt

Inconel 625 habena & coil

Mollis conditio et dura conditio cum superficie clara AB, latitudo usque ad 1000mm .

Inconel 625 Fasteners

Admiscere 625 fulmina offerre possumus, Nuces et alias clausuras pro clientibus requisitis

Inconel 625 Features:

1.High repunt, rupturas vires

2.Oxidation repugnant MDCCC °

3.Good lassitudine resistentia

4.Excellent weldability

5.Outstanding resistentia chloride pitting et rima corrosio

6.Immune ad chloride ion accentus corrosio crepuit

7.Resistant ad marinis sub utraque fluit et stagnantibus conditionibus et sub fouling

Inconel DCXXV Application agri

•Aircraft ducting systems

•Jet engine exhaurit systems

•Engine impulsus-reverso systems

•Follis et articulis expansion

•Turbine integumento annulos

•Flare acervos

•Aquae marinae components

•Apparatus processus chemica tractans acida mixta tum oxidizing et minuendo.

Nostra societas Products Forms

Bars & Rods

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless tube & iuncta tube

Nickel / Titanium Alloy tube

Bolt & Nuces

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 effect

Sheet & Plates

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Exue & Foil

Hastelloy / Inconel / invar / mollis magneticae Alloys effect

High Temperature Springs

Inconel 718/ Inconel x750/ Nimonic 80A

Wire & Welding

Filum Cobalt Alloy, filum Nickel offensionis, filum Tianium Alloy

Special Alloy Flanges

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oleum Tube Hanger

Inconel x750/ Inconel 718 / Monel 400 effect

Nickel Substructio Alloys

Welding Materials

Cobaltum Substructio Alloys

Special Steels

Subtilitas Alloys

Titanium Alloys

Discere More vel accipere vis?

Get in Touch

Quae materia 625 mixtura est?Nickel - mixturae fundatae cum alto Ni - Cr - Mo.

Chemical composition of Alloy 625: Chromium (Cr)20.0-23.0, Iron (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganesum (Mn)< 0.50, Nickel (Ni)258, sulphur (S)< 0.015, Cobalt (Co)< 1.0, (Mo) 8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015, (Nb) 3.15-4.15, Carbon (C)< 0.01.

625 Admisceri notae optimae oxidationis et corrosionis resistentiae, excellentiae roboris et duritiae, excellentis defatigatio resistentiae, altae formabilitas, et optimae copulationis.Virem suam et duritiam suam alicubi ab humilibus temperaturis ad MM°F conservare potest.Ob velocitatem mixturae offensionis 625, magna vis frigoris formandi furnum per frigus processus formandi requirat.Mixtura communiter in gagate machinas et alia aerospace applicationes adhibetur.